OUR PROJECTS

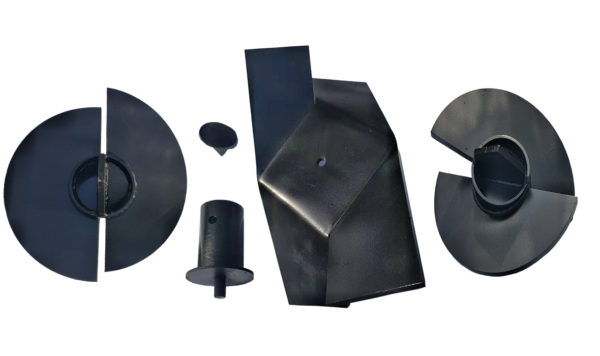

Duda Technology has rich project manage and operation experience in manufacturing sheet metal technique products for different industries, from multimedia kiosks terminals to logistic transport & storage equipment, from Auto Exhaust Piping Sytstems to Embedded parts for buildings. All those assembly are manufactured by sheet metal technique and this is what we have been devoted to all years along. Each production process is opimized by our expert at our ISO 9001:2015 certificated manufacturing base. Belive our next satisfactory project would be yours! Let us know your project specification for a better solution today!

LATEST PROJECTS

In FY 2018, we had mainly worked on below projects: Self service Kiosks metal structure for Bike sharing stations, wayfinding outdoor kiosks used in city center; stainless steel storage container, tank, trolley; Building Embeded parts, Auto Exhaust Pipes, Climbing Wall T-Nuts, Hopper Feed T-Nuts with Auto Machine. In 2019, we would like to expand production line.

PROJECT WORKING FLOW

Tuda Technology strictly follow project working flow for each OEM sheet metal assembly.

Check out below process flow to figure out what we have been done after receiving project invitaion from you.

| STAGE | Working Content | Working Goal | Responsible Position | Input Content | Output Content | Completion Time | Special Note |

|---|---|---|---|---|---|---|---|

| 1-Client Demand Analysis | Analyze product development intention, product style and function, establish customer experience-oriented quality standards | Decide whether or not to participate in project, if yes, go ahead and establish customer experience-oriented quality standards and costs. | a. Overseas Sales department: project leader. b. R&D Center head |

a. project application b. Product documents, including drawings, test requirement and etc.c. Project time plan |

Input review report | Within 3 working days after receiving client development project email | The project leader should fully prepare relevant information, call the right people in time to participate in the review |

| 2-Product Planning | Focus on customer requirements, product quality and cost objectives as a guide, to establish key elements: material technology, manufacturing technology, accessories supply, packaging, quality standards. | a. Establish competitive product development program. b. Effectively output of standard cost tables, pre-FMEA assessment documents and etc. |

a. project leader b. Related material Purchasing chief |

a. project application form b. product documentsc. input review report |

a. standard cost table b. spare parts supply informationc. PFMEA analysis |

Within the time frame specified in the project development time plan | Manufacturing process must be communicated and discussed with technical head |

| 3-Quote | a. Take cost analysis as foundation, take competitive strategy as the principle, establishes quote level b. follow quote feedback in time, if the price is not competitive, then make the decision whether or not to adjust the price in time |

Get an order at an ideal price and related terms | a. Overseas Sales department: project leader b.R&D center head |

a. Standard Cost Table b. PFMEA analysis |

a. Quote b. PFMEA analysis |

Quote should be offered within 3 working days after products documents received | The difficulty lies in scientifically determining the competitive strategy to get the order at the ideal price and terms. |

| 4-Confirm Internal Sample | Make appearance sample, evaluate with the sample meets products standard and represents the quality of lot products | Get customer approval for the sample | project leader | products documents | qualified sample to customer | within the project time frame | a. The means of mass production should be used. The sample quality should represent lot products. |

| 5-Customer confirmation for the sample | Customer will check the sample and do related tests. For some parts that may need adjust, secondary sample preparation should be conducted. | The sample could be confirmed | project leader | a. product document b. client’s comments for the sample |

Final sample | As time frame for project | Adjustment may needed for the first sample |

| 6- Lot production | Lot production- first delivery | First shipment should be delivered within required lead time | production manager | a. confirmed sample b. product final documents |

Qualified first shipment products | As client required | Pay attention to the risks points to avoid quality defects |

Would you be our partner? Yes, I do!

We have been treated each other like sisters, like brothers, like family. 10 years is just a blink of eye in the long river of history, but for Tuda, it’s been unforgettable years to blaze its way forward through all the difficulites and advancing victoriously. Each step of our dream could not be realized without your trust and support. Thank you~love you all!

NO OBLIGATION QUOTE TODAY

We know you are looking for a better sheet metal fabrication solution for your project, that’s why you are here. Or you just would like to discuss some industry trend with us. Just leave us a message.

Online contact and registration forms from Wufoo.

OFFICE LINE

+86 13074132058

SALES SUPPORT

sales@tdtechnology.com.cn

WORKING HOURS

9:00am – 6:00pm

OFFICE LINE

+86 13074132058

SALES SUPPORT

sales@tdtechnology.com.cn

WORKING HOURS